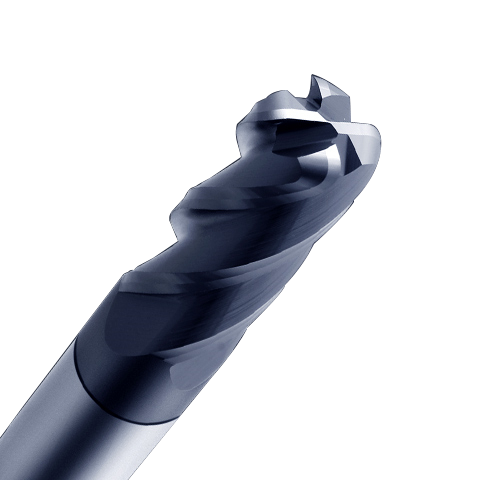

Tungsten Carbide Dovetail Milling Cutters cuab yeej

Qhov zoo

Tus nqi tsim nyog thiab peb xaiv cov khoom zoo tungsten steel nrog siab hardness thiab siab hnav tsis kam

Precision tshuab tsim, zoo sib tsoo. Precision ua, tsawg burrs hauv cov khoom ua-siab smoothness

Kev tswj xyuas nruj, siab precision thiab sharper tiav cov khoom

Feature

1. Ntse ntug cov ces kaum zoo heev txhim kho tej efficiency

2. Ncaj groove tsim, du nti tshem tawm tsis ua raws li riam

3. Tsim nyog zam huab cua thiab txuas lub neej ntawm lub cuab yeej

4. Ua kom muaj zog ntawm kev txiav ntug, thiab arc ntug siv yog ua rau lub ntsej muag ntse dua thiab tshem tawm burr zoo.

5. Lub peev xwm loj nti tshem tawm qhov zawj txiav qhov quab yuam, thiab kev txiav tau yooj yim dua, ua tiav kev ua haujlwm siab ua haujlwm, thiab cov khoom ua haujlwm zoo dua thiab txaus ntshai.

| Hom | Tungsten Dovetail Milling Cutter | Khoom siv | Tungsten hlau |

| Khoom siv ua haujlwm | Stainless hlau, txhuas, tuag hlau, cam khwb cia hlau, txhuas alloy, hlau alloy, titanium alloy, thiab lwm yam. | Siv tau tshuab cuab yeej | CNC machining chaw, CNC tshuab cuab yeej, tshuab engraving, engraving tshuab, high-speed tshuab |

| Thauj Pob | Lub thawv | Flute | 3/4 |

| Txheej | No | Hardness | <=55 |

| Flute Diameter (hli) | D2 (mm) | L2 (mm) | Flute Qhov siab (mm) | Txoj kab uas hla (mm) | Tag nrho Length (mm) | Flutes |

| 3 | 1.5 | 5 | 0.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 1.2 | 5 | 50 | 3 |

| 6 | 3 | 8 | 1.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 1.7 | 7 | 50 | 4 |

| 8 | 4 | 10 | 2 | 8 | 50 | 4 |

| 9 | 4.5 | 15 | 2.2 | 9 | 60 | 4 |

| 10 | 5 | 15 | 2.5 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 2.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 3 | 12 | 60 | 4 |

| 16 | 8 | 20 | 4 | 16 | 65 | 4 |

| 20 | 10 | 25 | 5 | 20 | 75 | 4 |

| 3 | 1.5 | 5 | 1.4 | 3 | 50 | 3 |

| 4 | 2 | 6 | 1.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 2.1 | 5 | 50 | 3 |

| 6 | 3 | 8 | 2.6 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 3 | 7 | 60 | 4 |

| 8 | 4 | 10 | 3.4 | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 3.8 | 9 | 60 | 4 |

| 10 | 5 | 15 | 4.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 4.7 | 11 | 60 | 4 |

| 12 | 6 | 15 | 5.2 | 12 | 60 | 4 |

| 16 | 8 | 20 | 6.9 | 16 | 65 | 4 |

| 20 | 10 | 25 | 8.6 | 20 | 70 | 4 |

| 3 | 1.5 | 5 | 2.7 | 3 | 50 | 3 |

| 4 | 2 | 6 | 3.7 | 4 | 50 | 3 |

| 5 | 2.5 | 8 | 4.6 | 5 | 50 | 3 |

| 6 | 3 | 8 | 5.5 | 6 | 50 | 3 |

| 7 | 3.5 | 10 | 6.5 | 7 | 60 | 4 |

| 8 | 4 | 10 | 7.4 ib | 8 | 60 | 4 |

| 9 | 4.5 | 15 | 8.3 | 9 | 60 | 4 |

| 10 | 5 | 15 | 9.3 | 10 | 60 | 4 |

| 11 | 5.5 | 15 | 10.2 | 11 | 60 | 4 |

| 12 | 6 | 15 | 11.1 | 12 | 60 | 4 |

| 16 | 8 | 20 | 14.9 Nws | 16 | 65 | 4 |

| 20 | 10 | 25 | 18.6 ib | 20 | 75 | 4 |

Siv

Dav siv nyob rau hauv ntau lub teb

Aviation Manufacturing

Tshuab Ntau Lawm

Tsheb tsim

Pwm ua

Hluav taws xob Manufacturing

Tshuab dhos ua

Q1: Kuv puas tuaj yeem muaj tus qauv rau kev kuaj?

A: Yog lawm, peb tuaj yeem txhawb nqa tus qauv. Cov qauv yuav raug them tus nqi tsim nyog raws li kev sib tham ntawm peb.

Q2: Kuv puas tuaj yeem ntxiv kuv lub logo rau ntawm lub thawv / thawv?

A: Yog, OEM thiab ODM muaj nyob ntawm peb.

Q3: Dab tsi yog qhov txiaj ntsig ntawm kev ua tus xa khoom?

A: Kev txo nqi tshwj xeeb Kev Tiv Thaiv Kev Lag Luam.

Q4: Koj tuaj yeem tswj cov khoom zoo li cas?

A: Yog lawm, peb muaj engineers npaj los pab cov neeg siv khoom nrog cov teeb meem kev txhawb nqa, txhua yam teeb meem uas yuav tshwm sim thaum lub sij hawm quoting lossis installation txheej txheem, nrog rau kev txhawb nqa tom qab muag. 100% kev tshuaj xyuas tus kheej ua ntej packing.

Q5: Kuv puas tuaj yeem tuaj xyuas koj lub Hoobkas ua ntej kev txiav txim?

A: Tseeb, txais tos koj tuaj xyuas ntawm lub Hoobkas.