Me Txoj kab uas hla HSS Extrusion Threading kais

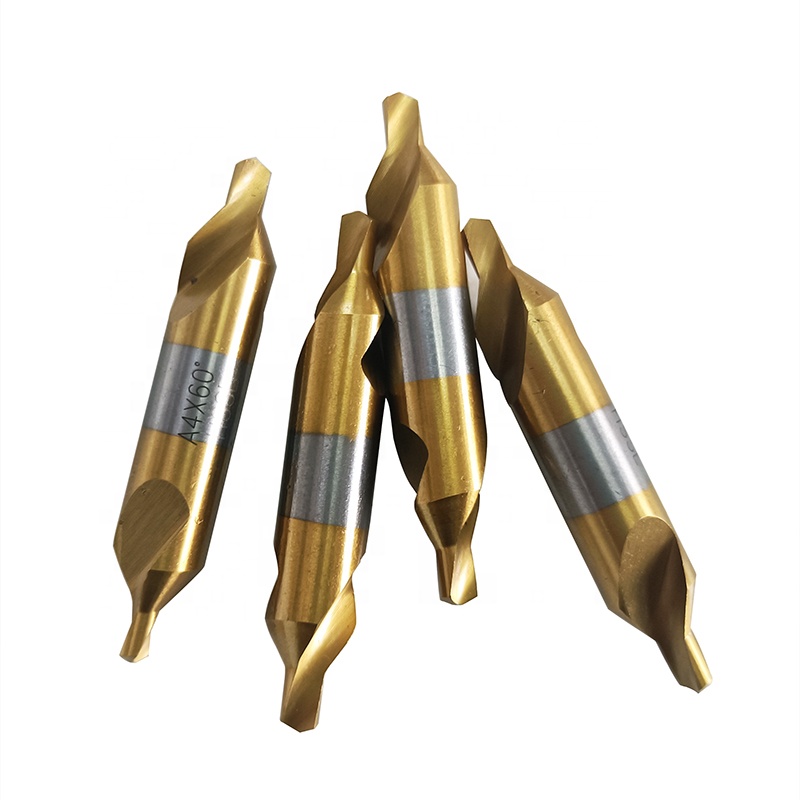

Product Description

Tsim los ntawm qib hwm High Speed Cobalt (HSS) kom muaj zog ntxiv thiab toughness, txhim kho ntug zog thiab lub neej ntev dua.

Qhov zoo

1. Cov khoom siv tungsten steel, xaiv zoo tungsten steel tuav, nrog ultra-siab hnav tsis kam thiab siab toughness.

2. Extrusion kais tsim, ultra-fine particle siab kub resistant txheej, ua kom durability

3. Kev sib tsoo tag nrho, zoo sib tsoo kauv zawj, optimized kauv tsim, du nti tshem tawm yam tsis ua raws li riam, zoo heev txhim kho kev ua hauj lwm efficiency

Tswv yim

1. Tsim nyog txo qhov txiav ceev thiab pub tus nqi, uas tuaj yeem ua rau lub neej ntev kev pab cuam ntawm lub tshuab txiav milling

2. Thaum ua hauj lwm, nws yog ib qho tsim nyog yuav tsum tau ntxiv cov kua txiav los tiv thaiv riam ntug, kom cov txiav yog smoother

3. Qhov ntev ntawm lub cuab yeej protruding los ntawm chuck, qhov zoo dua. Yog hais tias lub protruding ntev ntev, thov txo qhov ceev los yog pub tus nqi ntawm koj tus kheej

| Khoom npe | Me Diameter Kauv Flute Carbide Ntsia Hlau Threading kais | Khoom siv tau | Titanium alloy, stainless hlau, magnesium alloy, tuag-cam khwb cia txhuas | |||

| Hom | XINFA | Txheej | Yog lawm | |||

| Khoom siv | HSS | Siv cov cuab yeej siv | tshuab dhos | |||

| L | 1 | Dn | In | D | K | lk |

| 30 | 3.5 | 1.1 | 7 | 3.0 | 2.5 | 5 |

| 32 | 3.5 | 1.3 | 7 | 3.0 | 2.5 | 5 |

| 34 | 4.2 | 1.5 | 8 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.7 | 9 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.8 | 9 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.9 | 9 | 3.0 | 2.5 | 5 |

| 40 | 5.6 | 2.1 | 10 | 3.0 | 2.5 | 5 |

| 42 | 6.3 | 2.3 | 10 | 3.0 | 2.5 | 5 |

| 42 | 5.6 | 2.4 | 10 | 3.0 | 2.5 | 5 |

| 44 | 6.3 | 2.6 | 11 | 3.0 | 2.5 | 5 |

| 44 | 6.3 | 2.7 | 11 | 3.0 | 2.5 | 5 |

Cov txiaj ntsig ntawm cov neeg siv khoom

1. Kev ua haujlwm siab thiab kev tsim khoom hauv ntau yam khoom siv.

2. Chamfer hom C tuaj yeem siv rau ob qho tib si dhau los thiab qhov muag tsis pom.

3. Chip-dawb threading lag luam tsim cov xov muaj zog dua li txiav cov kais dej uas muaj peev xwm ua tau ntau dua. Kev txiav nrawm dua yog, yog li, pom zoo.

4. Ntau dua qhov tseeb ntawm cov xov tiav nrog qis dua qhov roughness.

5. Kev tsim qauv ruaj khov txhais tau tias tsis tshua muaj kev pheej hmoo ntawm kais tawg thiab cov txheej txheem kev ruaj ntseg zoo.

6. Cov kev xaiv roj zawj ua kom cov dej txias ntws mus rau thaj chaw machining, ntxiv cov cuab yeej siv lub neej.

Siv

Dav siv nyob rau hauv ntau lub teb

Aviation Manufacturing

Tshuab Ntau Lawm

Tsheb tsim

Pwm ua

Hluav taws xob Manufacturing

Tshuab dhos ua

Q1: Kuv puas tuaj yeem muaj tus qauv rau kev kuaj?

A: Yog lawm, peb tuaj yeem txhawb nqa tus qauv. Cov qauv yuav raug them tus nqi tsim nyog raws li kev sib tham ntawm peb.

Q2: Kuv puas tuaj yeem ntxiv kuv lub logo rau ntawm lub thawv / thawv?

A: Yog, OEM thiab ODM muaj nyob ntawm peb.

Q3: Dab tsi yog qhov txiaj ntsig ntawm kev ua tus xa khoom?

A: Kev txo nqi tshwj xeeb Kev Tiv Thaiv Kev Lag Luam.

Q4: Koj tuaj yeem tswj cov khoom zoo li cas?

A: Yog lawm, peb muaj engineers npaj los pab cov neeg siv khoom nrog cov teeb meem kev txhawb nqa, txhua yam teeb meem uas yuav tshwm sim thaum lub sij hawm quoting lossis installation txheej txheem, nrog rau kev txhawb nqa tom qab muag. 100% kev tshuaj xyuas tus kheej ua ntej packing.

Q5: Kuv puas tuaj yeem tuaj xyuas koj lub Hoobkas ua ntej kev txiav txim?

A: Tseeb, txais tos koj tuaj xyuas ntawm lub Hoobkas.